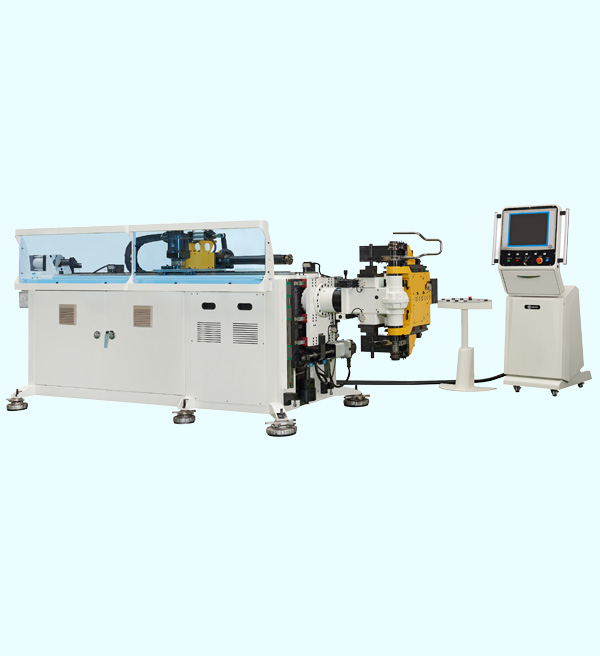

Yida ML-600M (2-axis)

The Yida ML-600M is a cutting-edge 2-axis CNC turning center designed to deliver unmatched precision and efficiency. Ideal for a wide range of machining applications, this robust machine offers exceptional reliability and performance.

ML-Series CNC Lathes: Compact and Built for Precision

The ML-Series CNC Lathes are engineered with a compact machine structure that delivers exceptional performance in a streamlined design. Every structural component is crafted from high-quality cast iron and undergoes stress relief treatment to eliminate deformation, ensuring long-term reliability.

To enhance durability and precision, the structural parts are reinforced with scientifically designed ribs, minimizing vibration and deflection. During the design process, finite element analysis (FEA) is applied to simulate various stress conditions, resulting in superior vibration resistance and structural integrity.

The slant-bed design not only maximizes stability during cutting operations but also ensures efficient chip evacuation, providing a cleaner and more productive machining environment. The ML-Series is the ideal solution for manufacturers seeking robust, high-performance CNC lathe solutions.

- Slant bed design

- High quality cast iron

- Box ways on X, Y, Z axes

- Twin spindles/ single turret

Machine Technical Features

Advanced Machining Capabilities

CS-Axis Function

The CS-axis functionality, combined with a live tooling turret, transforms the machine into a versatile solution capable of milling, drilling, and tapping operations — all in a single setup. Equipped with a high-precision rotary encoder, the CS-axis ensures exceptional orienting accuracy for complex machining tasks.

Y-Axis Function

The Y-axis is designed for precision and stability, featuring a lightweight structure that is directly driven by a servo motor for high positioning accuracy. Box ways enhance stability during cutting, while the 100mm travel range (±50mm) allows for efficient machining of various workpieces. This setup enables high-speed, accurate operations, ensuring consistent results.

Sub-Spindle

The sub-spindle streamlines the machining process by picking up the workpiece directly from the main spindle through simple programming. This capability allows for seamless machining of the other side of the workpiece, eliminating downtime for loading and unloading. The result is reduced cycle times and increased productivity, making it ideal for high-volume or complex part manufacturing.

These advanced features work in harmony to deliver a powerful, efficient, and precise machining experience, catering to a wide range of industrial needs.

Experience unmatched precision and performance

Our Products

Discover Our Innovative Solutions

Office

-

Egypt

PROMECH Engineering HQ ( Cairo Office ) Egypt Nile Tower – Second floor office A1, Corniche El-Nile Maadi – Cairo

-

KSA

ULTIMATE SOLUTIONS – AlShorbatli Plaza -4th floor – Office 406 – Western AlBogdadeyah, Extra#: 8585 – Bulding# 3827 | P.O. Box: 22234

-

UAE

Abu Dhabi office: Masdar city incubator building | P.O 3560